At GIG, we love celebrating our members’ inspiring achievements, and we cannot wait to share this inspiring collaboration story we have witnessed from a GIG member this year.

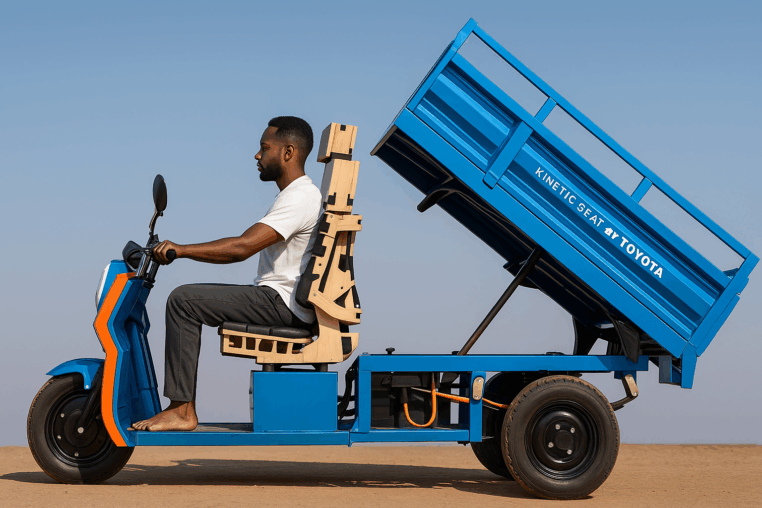

What happens when a local makerspace in Kenya partners with one of the world’s largest car manufacturers? A revolutionary seat that moves like the human spine, transforming how rural farmers in Africa navigate bumpy roads. This trans-continental collaboration between FabLab Winam and Toyota Motor Corporation – a high-class automotive manufacturer – has created an innovation that could enhance mobility across Africa.

Martin Oloo drives this remarkable partnership as co-founder of Fablab Winam, a Kisumu-based innovation hub, revolutionising how young Kenyans approach manufacturing and equipping the next generation with hands-on skills.

Sparking collaboration

Sometimes, simple introductions ignite extraordinary collaborations. When Martin first connected with Eng. Kohshi Katoh, a Toyota engineer participating in the 2025 Fabricademy programme through a mutual mentor, could not predict what would unfold. Koshi needed a local partner for his Fabricademy project; Martin was drive into passion to address the daily struggles of rural farmers facing transportation challenges in his community.

Their initial conversations revealed a shared vision: what if they reimagined automotive innovation through the lens of local community needs? Soon after, Kohshi packed his bags for a three-week immersive collaboration at FabLab Winam, ready to experience firsthand the challenges that inspired their partnership.

The challenges

The collaboration began by understanding the stark reality that Kenya’s farming communities face in transportation that directly impacts their livelihoods. Roads become muddy after rain, riddled with potholes, and challenging to navigate across rocky terrain. These conditions limit travel to motorbikes, forcing farmers to walk with goods or rely on inefficient transport that cannot handle large-scale loads. Martin shares that farmers often lose goods before reaching markets and experience health-related issues from air pollutants.

Since Kenya imports over 90% of vehicles at high tax rates, most smallholder farmers cannot afford cars or tuk-tuks that could carry larger loads, given their minimal daily income. These transportation challenges compound the community’s unemployment crisis, as young people avoid farming because they view it as labor-intensive with slow returns—a perception shaped by the lack of efficient farming vehicles. This creates a cycle where transportation barriers limit economic opportunities and perpetuate poverty.

The solution

Rather than attempting to dramatically lower vehicle costs—an impossible feat—the duo focused on improving comfort in readily accessible vehicles for Kenyan farmers, namely two and three-wheeled wagons. The FabLab Winam team gathered local farmers’ perspectives through town hall meetings, where many emphasised that poor road conditions demanded seats designed for comfort across different surfaces. These insights sparked Koshi’s adaptation of a kinetic seat that he had already been working on at Toyota.

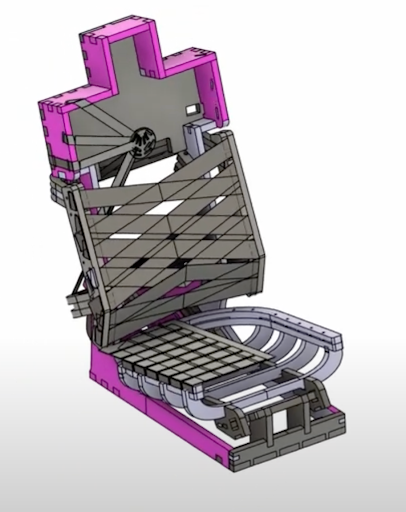

The seat stabilises the head and body by mimicking spine function—imagine how your spine naturally flexes when you walk to absorb impact. The flexible seat moves with human spine movement, providing enhanced comfort and mobility. The kinetic seat features two rotational axes: one at the pelvic level and one in the backrest at chest level. When centrifugal force moves the seat back, the spine meets between these axes, significantly reducing head movement compared to standard seats, especially on bumpy roads.

The duo’s key objective was to make this innovation accessible to small Kenyan farmers as a “Made in Kenya” product utilising “FabLab-able” materials and low-cost design approaches. The prototype uses plywood CNC milling and recycled car seat belts, and there are plans to create open documentation designed specifically for FabLab fabrication down the road.

The prototyping process

Over several months, FabLab Winam and Koshi collaborated on prototyping and testing through an iterative design process. The team explored sustainable materials that were breathable, recyclable, lightweight, and generated less heat. They repurposed discarded car seat belts as their primary material.The frame design required creative thinking. Instead of standard steel frames that demand complex sheet metal processing, they chose wooden seat frames—a sustainable and inexpensive innovation that Koshi attributes to his Fabricademy experience.

Over two months, they explored FabLab-compatible designs, testing different wood types before achieving success with plywood for CNC milling. The collaboration spanned continents seamlessly. After Toyota conducted a strength analysis and finalised the prototype design in Japan, they sent the data to FabLab Winam for fabrication and assembly.

The real test came when the team took their creation onto Kenya’s notorious roads, navigating mud and potholes that challenge any vehicle. The results exceeded expectations. FabLab Winam members found the ride pleasant and relaxing, particularly noting reduced head movement. This real-world testing revealed structural improvements for future iterations while proving the concept worked. Watch the team’s prototyping session on the ground on Youtube here.

Throughout the entire prototyping process, farmers remained central to the development process. Through feedback sessions and co-creation workshops, they shared what worked and what needed improvement, ensuring the final design would truly serve their needs on Kenya’s challenging terrain.

Future plans and applications

The team plans to redesign existing bikes and develop seat frames using local materials like bamboo, fish skin, papyrus, and water hyacinth.

Currently focusing on waste management and farming applications across Africa, they have built successful prototypes of two and three-wheeled wagonss while developing a homemade tractor to attract young people to farming. This cross-cultural collaboration has even improved Toyota’s sports cars, where engineers tested the FabLab kinetic design against traditional seats.

For Martin, the collaboration provided valuable insights about rapid prototyping and design, particularly how “prototyping with the client together strengthens the value of the design” and how “Fablabs have the capability to create big value in their communities with the right partnerships.”

Martin envisions a sustainable manufacturing ecosystem for vehicles in his community. This model would train young people in quality manufacturing processes, source materials from local suppliers, and produce spare parts locally.

Beyond addressing Kenya’s challenging road conditions, he believes the project will create jobs, improve crop yields, and deepen research into local resources. He also believes that the initiative will strengthen community engagement as more people appreciate digital fabrication and prototyping.

Meaningful two-way impact

This collaboration demonstrates how makerspaces and corporations can create meaningful impact together. Toyota brings resources, technical expertise, and global reach, while FabLab Winam contributes local knowledge, creativity, and context-driven problem-solving. Both sides benefit: corporations discover fresh perspectives and agile innovation approaches, while makerspaces gain pathways for scaling ideas, creating jobs, and empowering communities.

It is proof that impactful solutions emerge at the intersection of global knowledge and local necessity, not in isolation. When established companies embrace grassroots innovation, they unlock sustainable solutions that address real-world challenges while fostering community transformation.